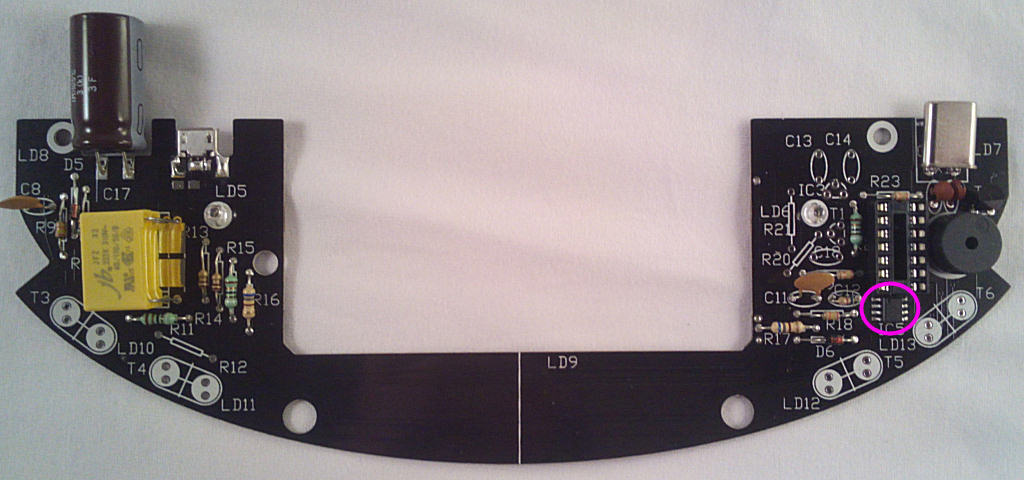

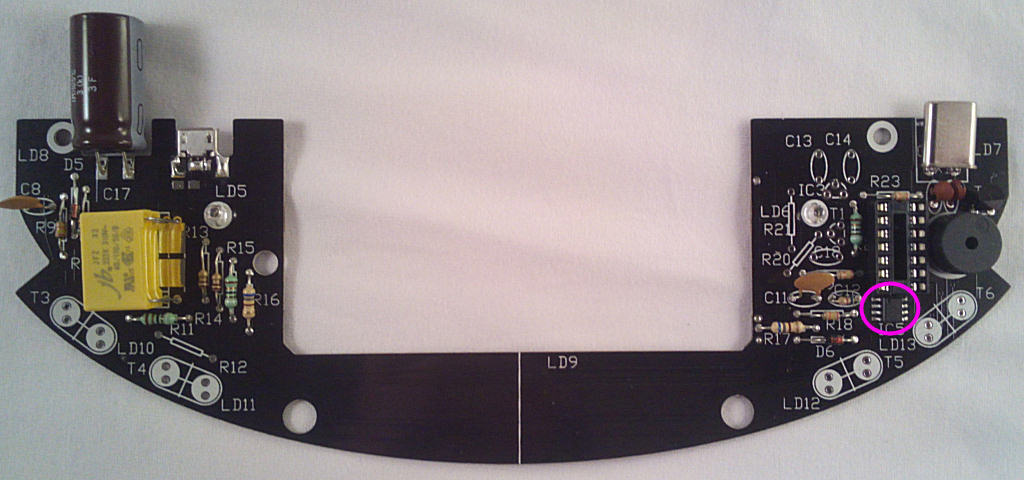

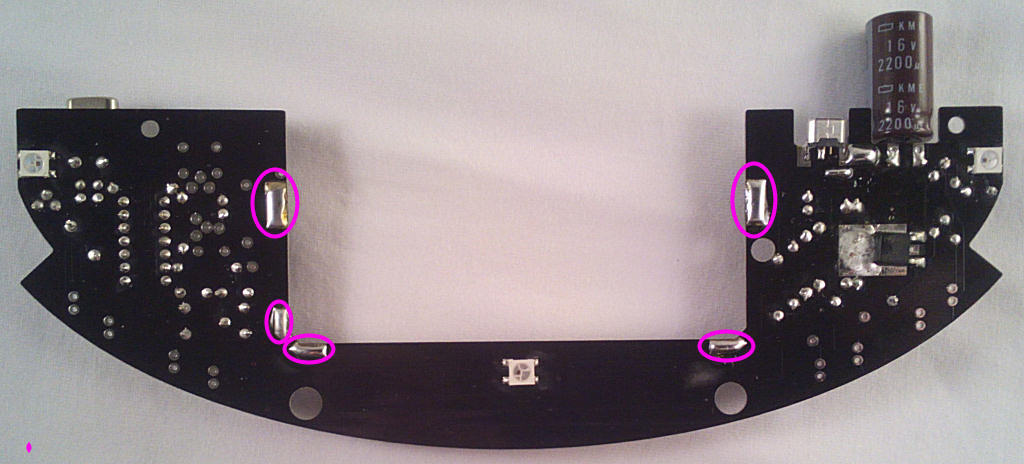

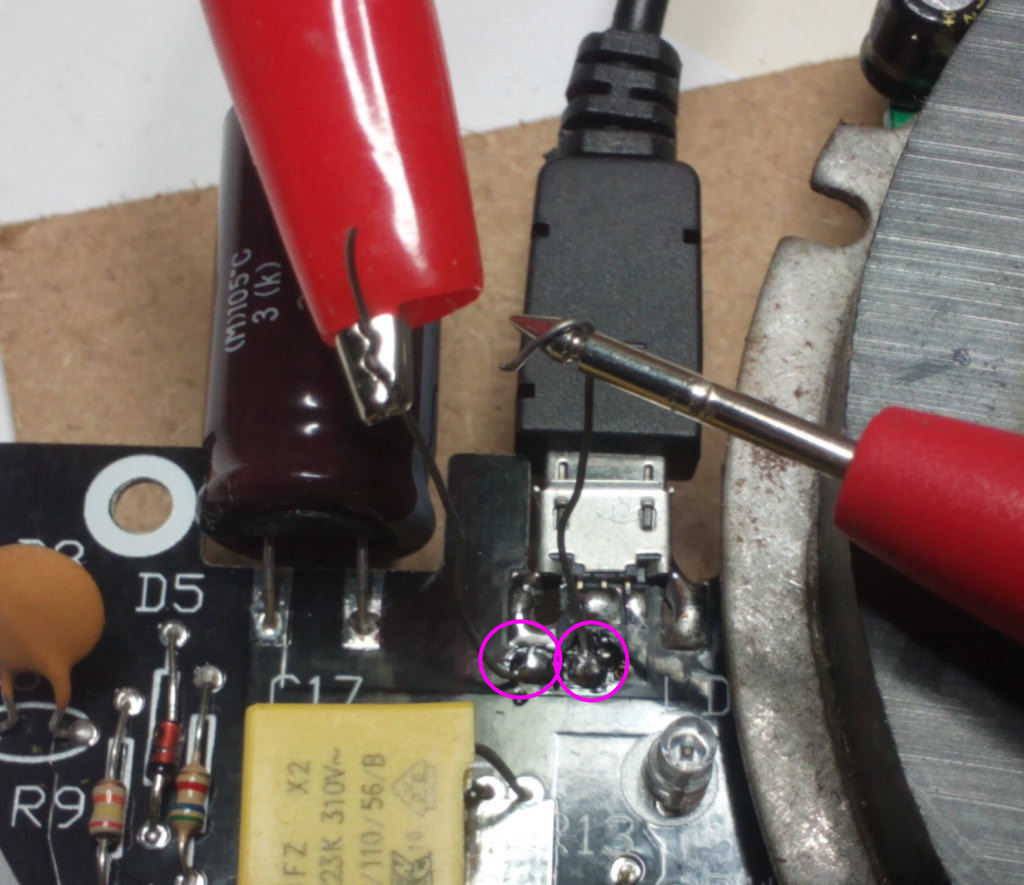

Now it's time for the first power-on test. Connect the base to the power PCB using the supplied micro-USB cable and switch on. The current reading should be about 100mA, more if one of the LEDs randomly decided to light up. It shouldn't be more than about 140-160mA if so.

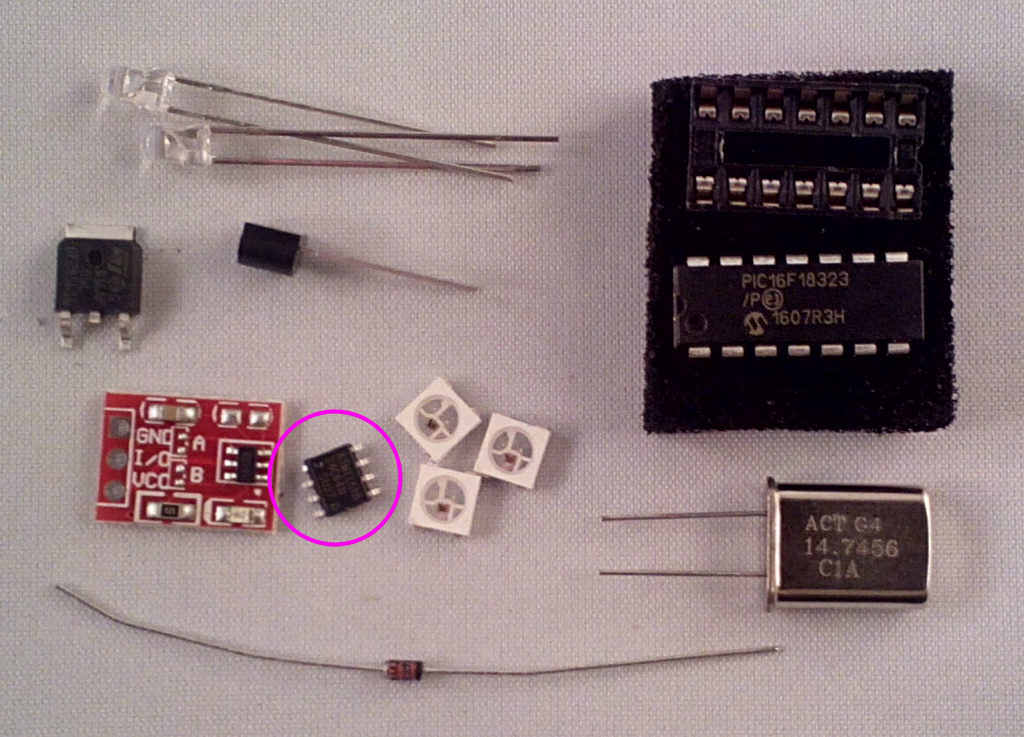

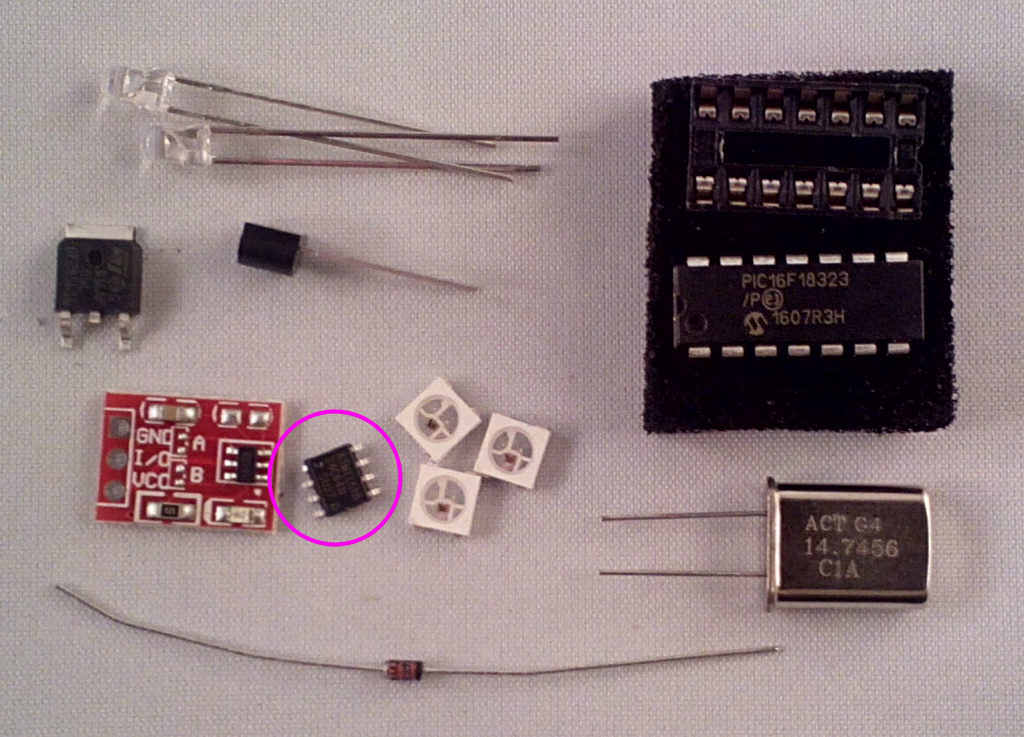

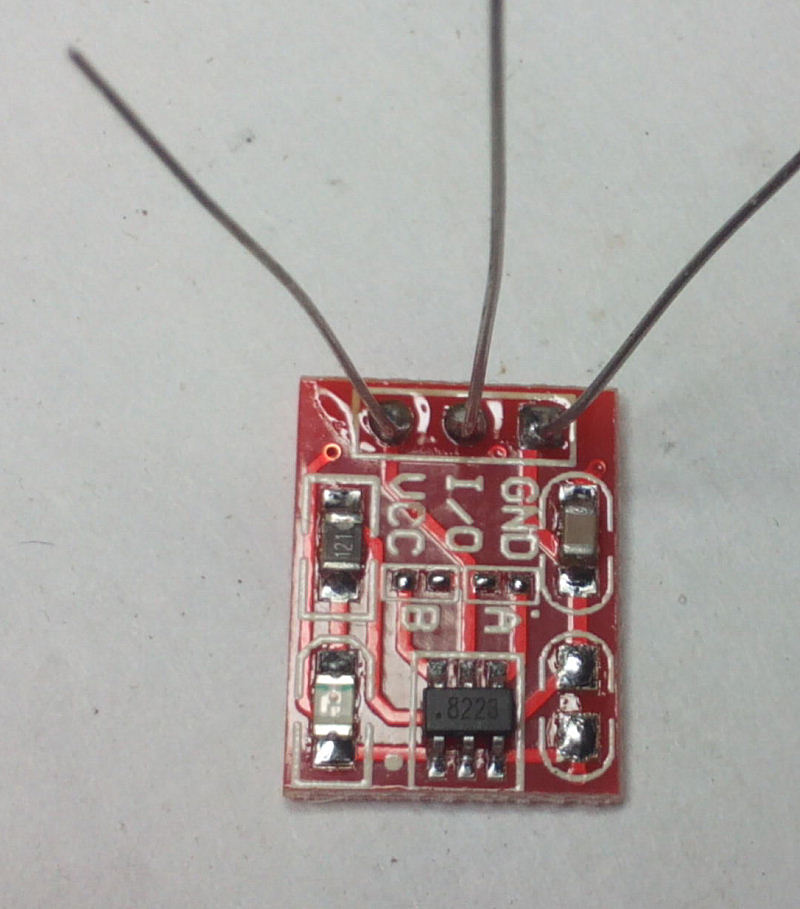

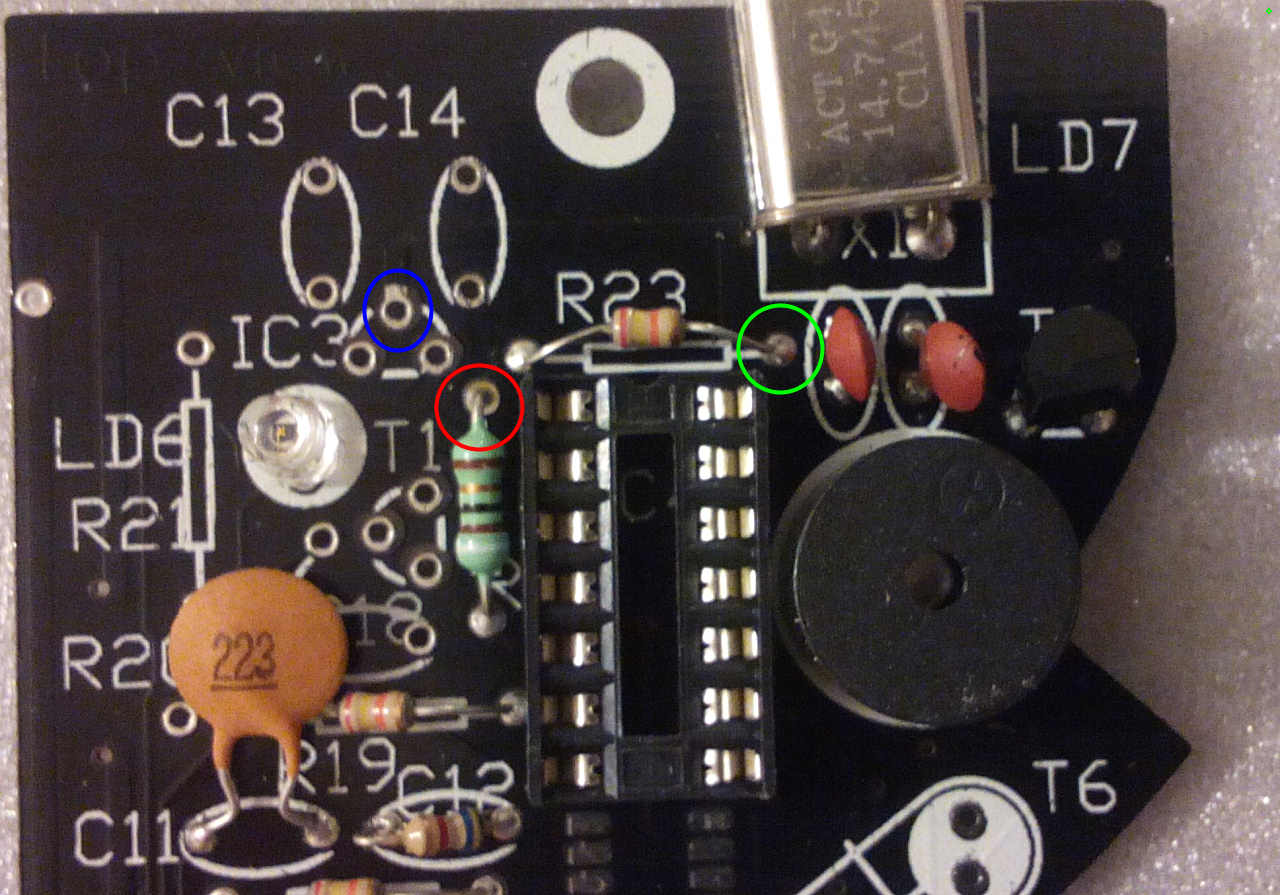

Switch off and fit IC4, then switch on again. The current reading should be almost the same, the LEDs will flash green for a second then go out. Put your finger near the touch switch, the LED on it should light up and LS1 will start to beep with a tone increasing in frequency the longer the switch is held.

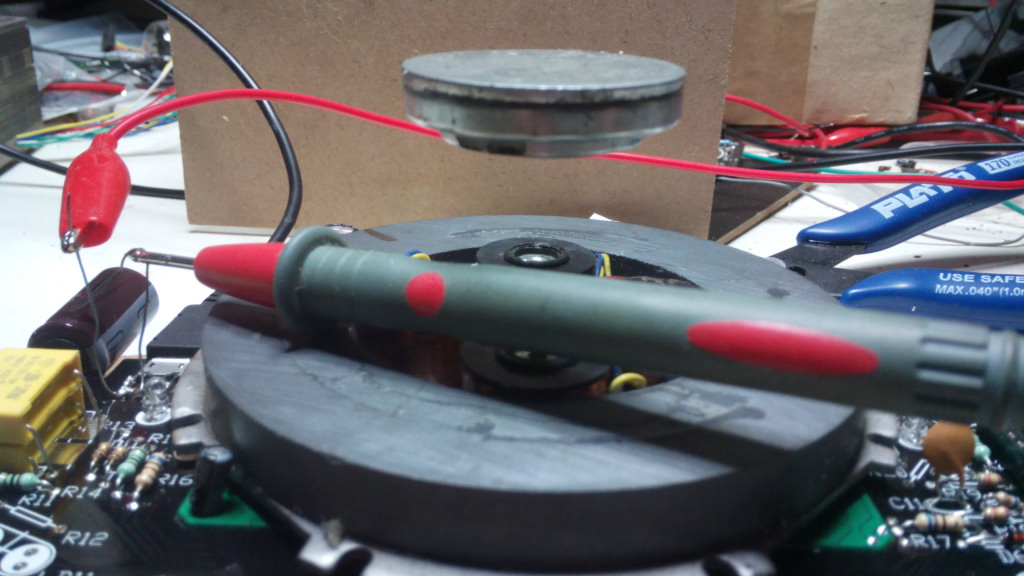

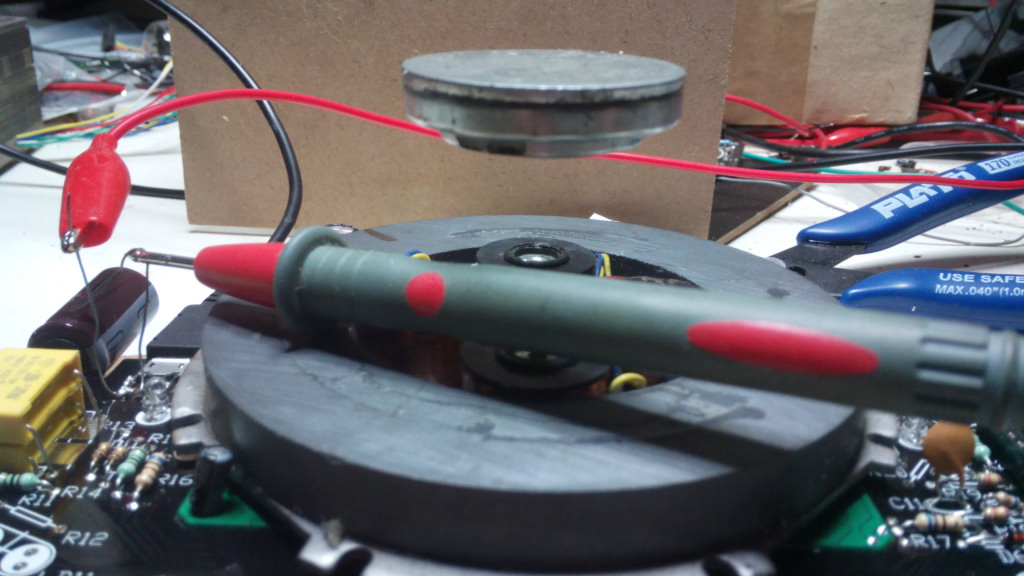

Try carefully floating the small magnet included in the 'relay' kit box, as it's a bit light just now it will tend to slip easily to one side but should still float with care.

Now jump to the coil winding instructions for the rest of the assembly.