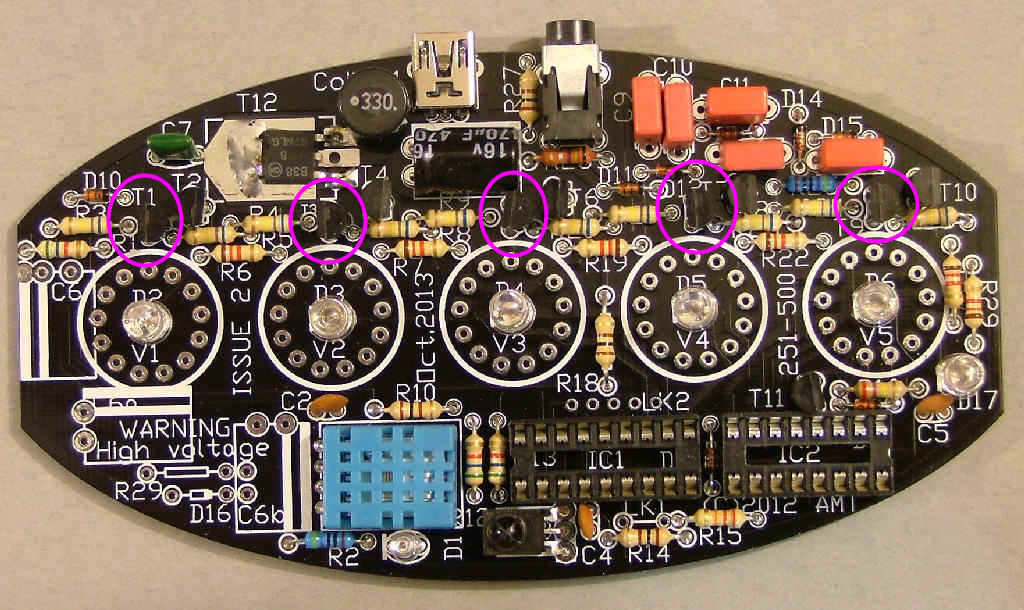

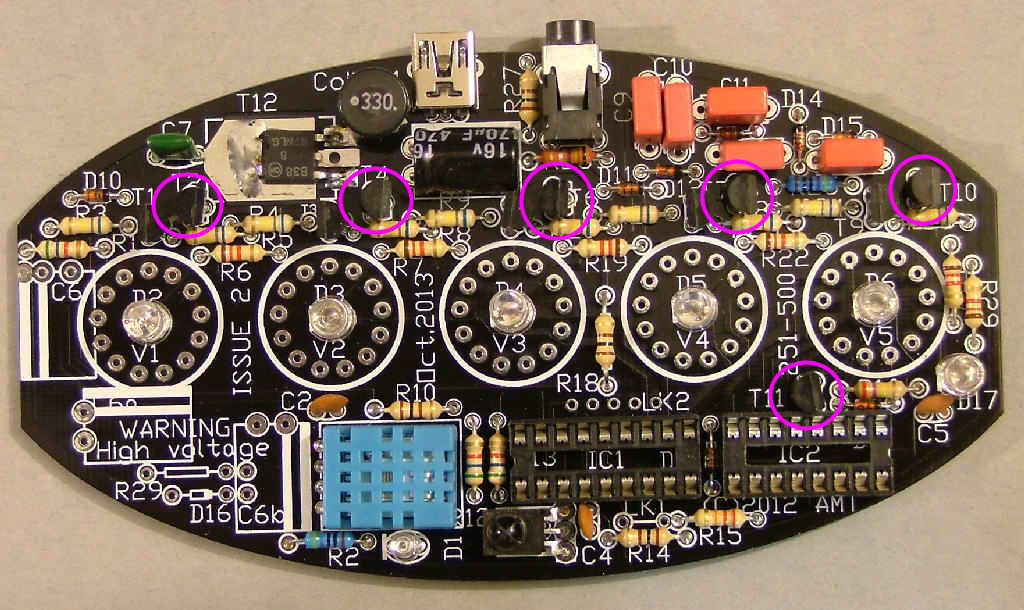

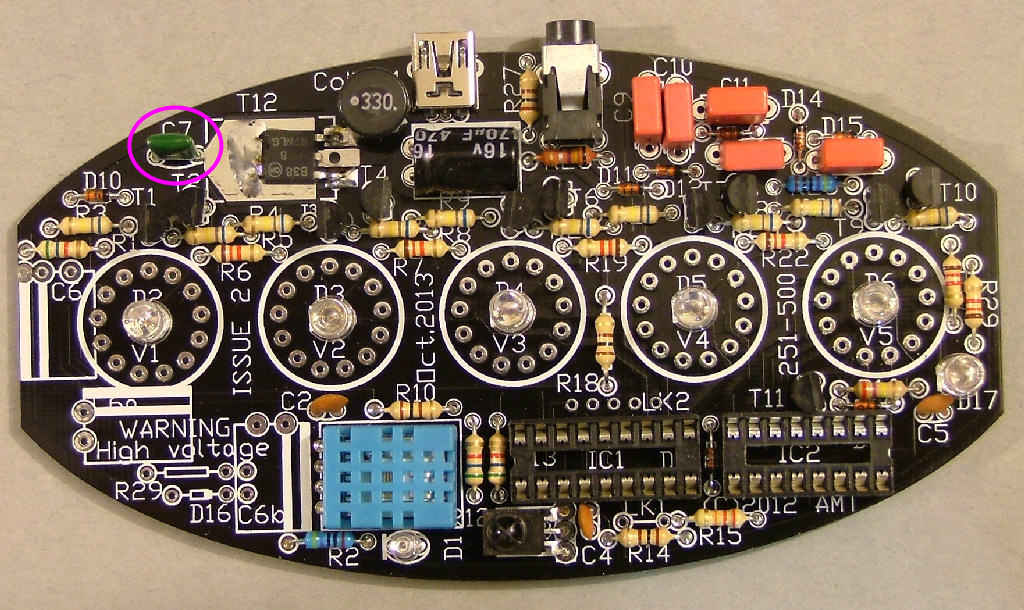

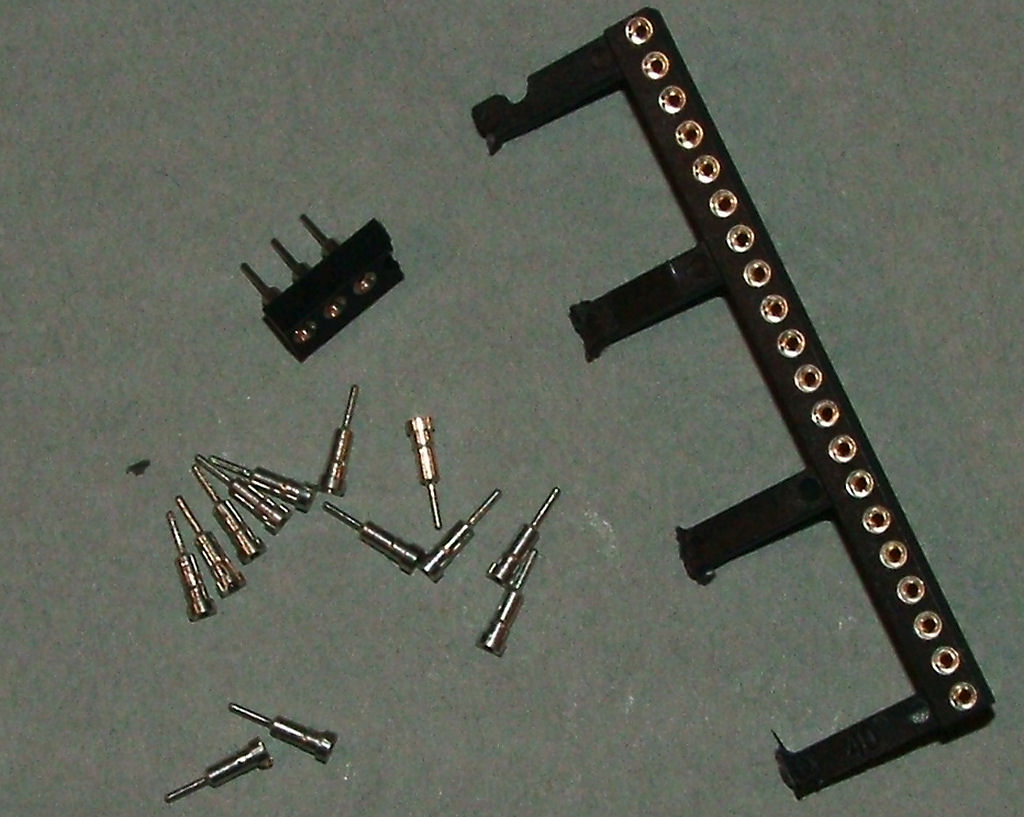

Using wirecutters or pliers carefully break the turned pin sockets out of the plastc housing:

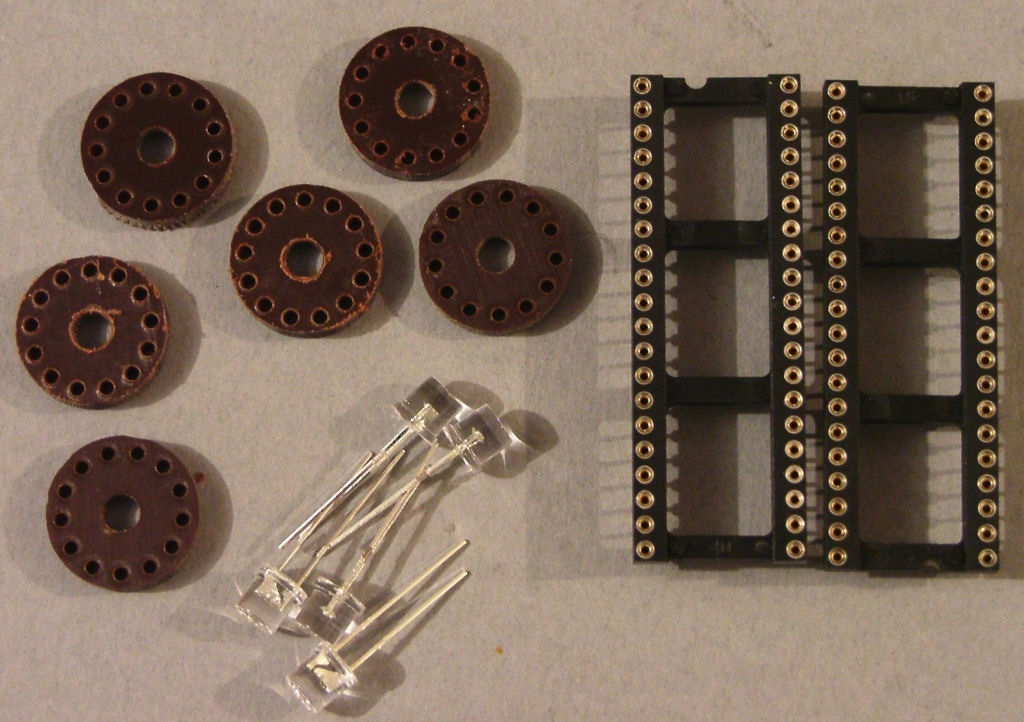

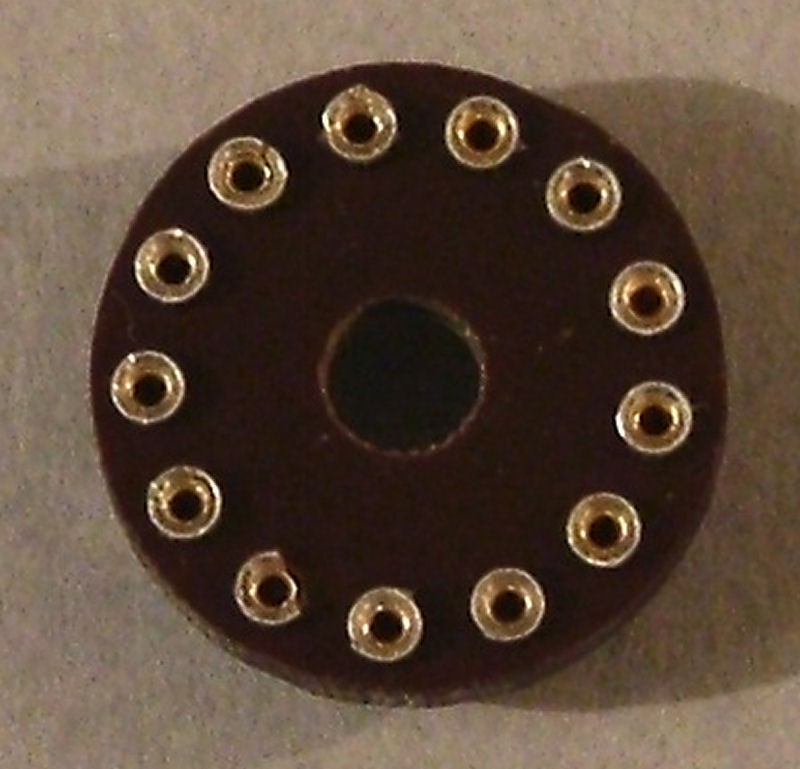

Push the pins into the holder:

Once made, drop them into the V1-5 positions on the PCB and solder them in place.

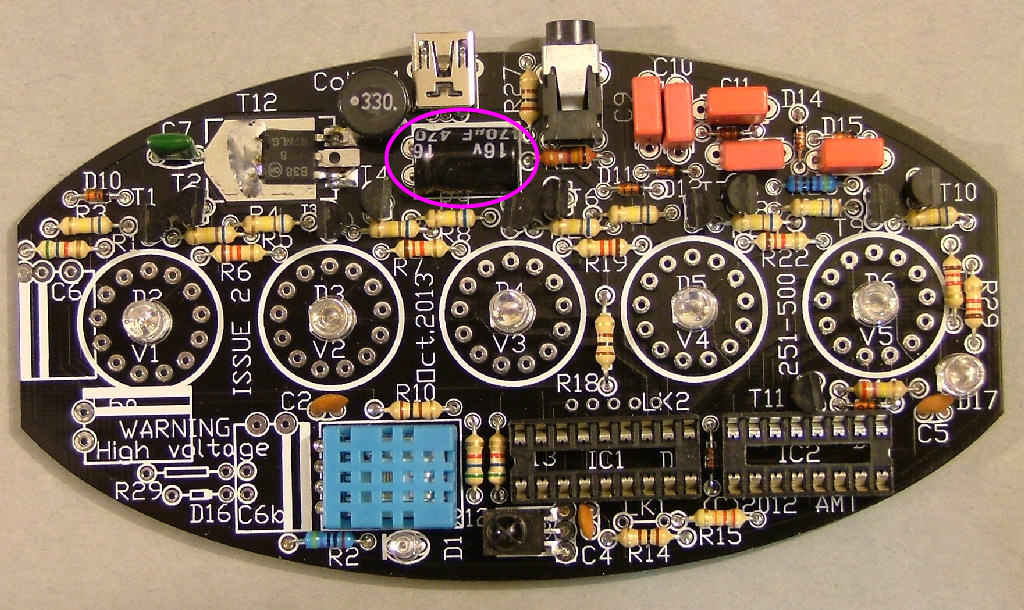

Now fit the LEDs through the centre hole so they sit on top of the socket. NOTE that these are polarised and must be fitted the right way round. The SHORT PIN faces to the LEFT of the PCB when viewed from the front.

D17 is no longer used.